Stress Strain Behavior Determination Ceramics

Calculate the resulting strain.

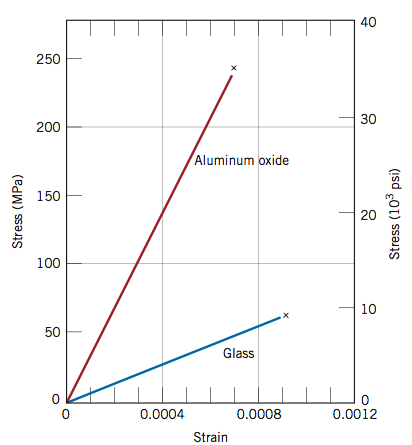

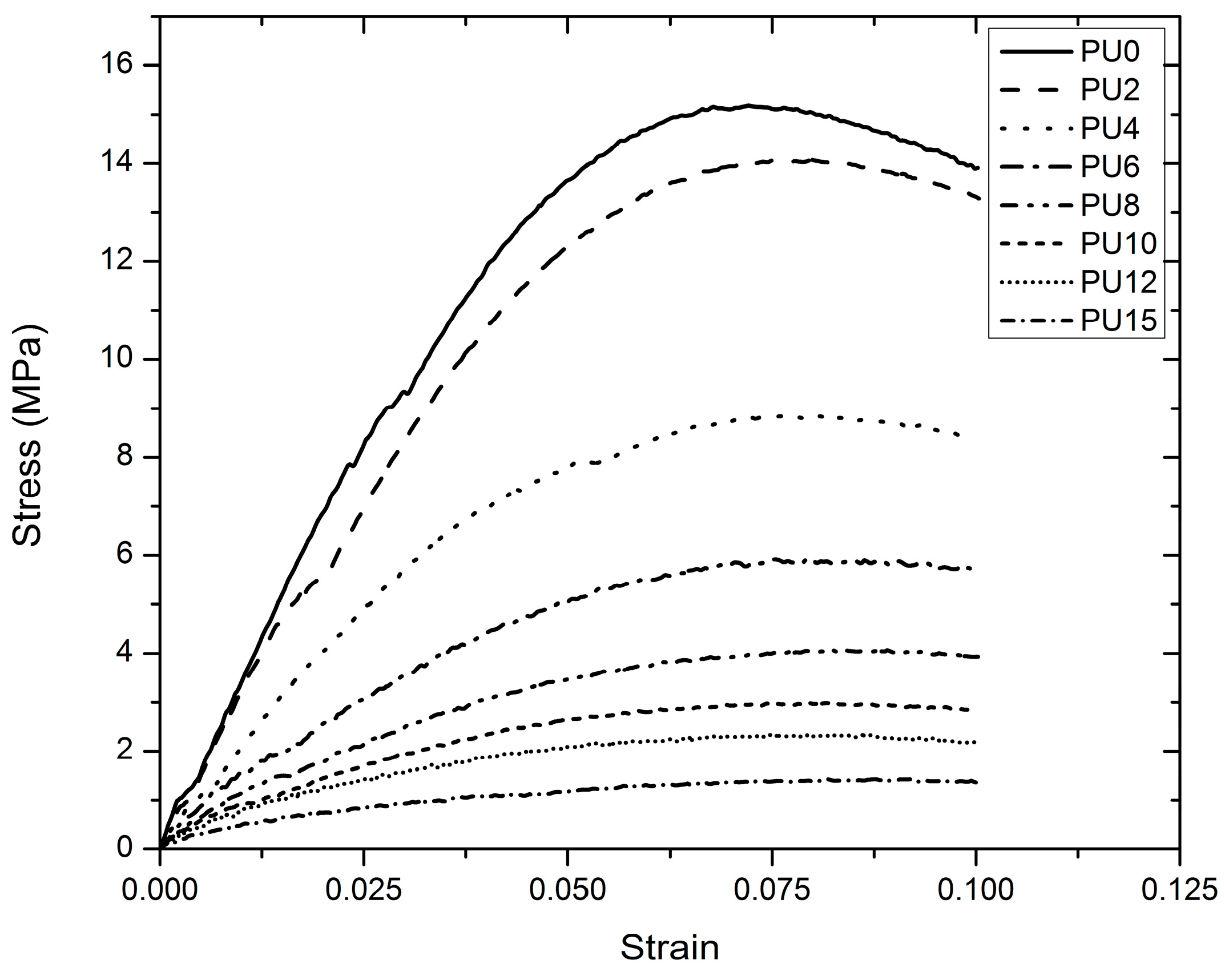

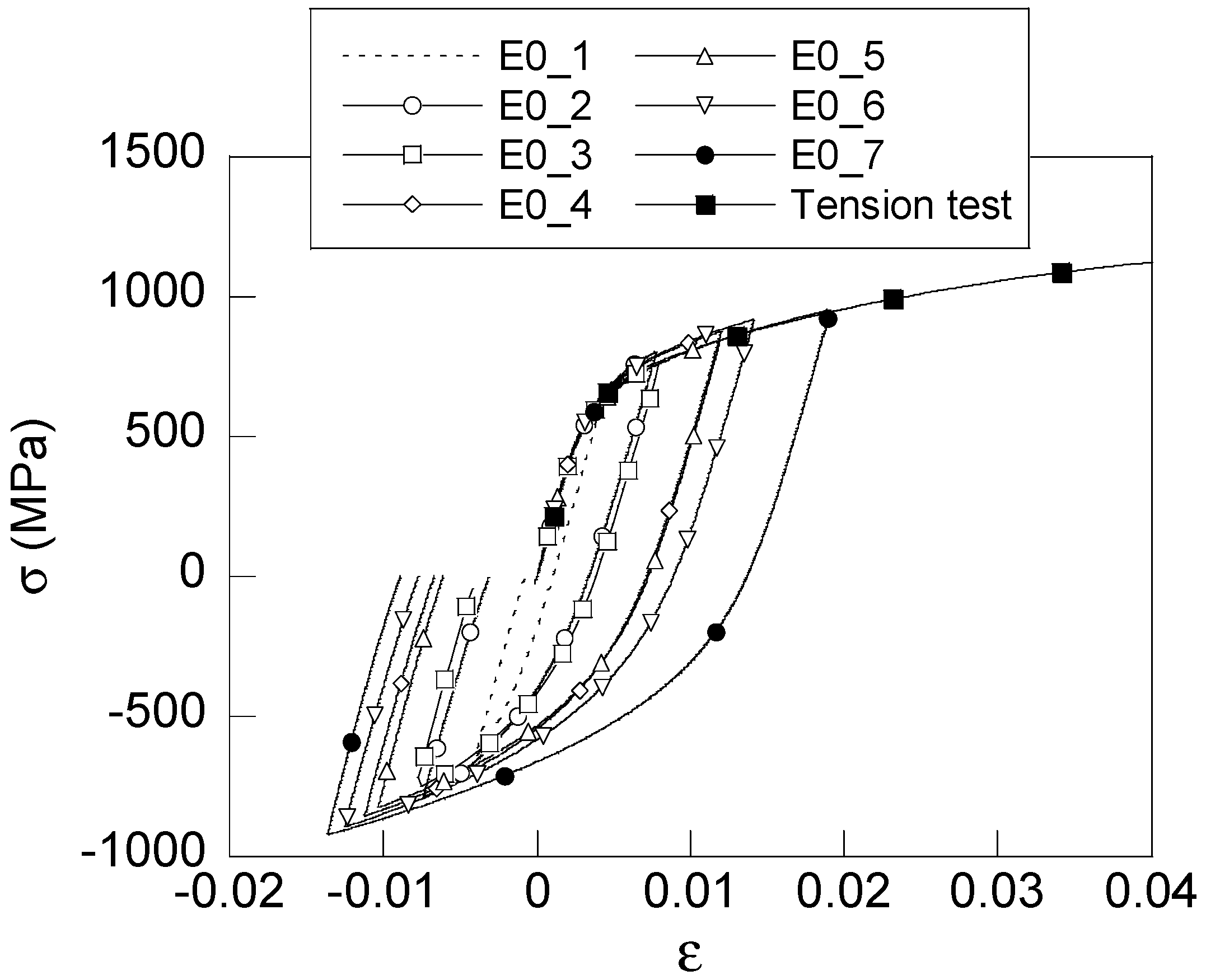

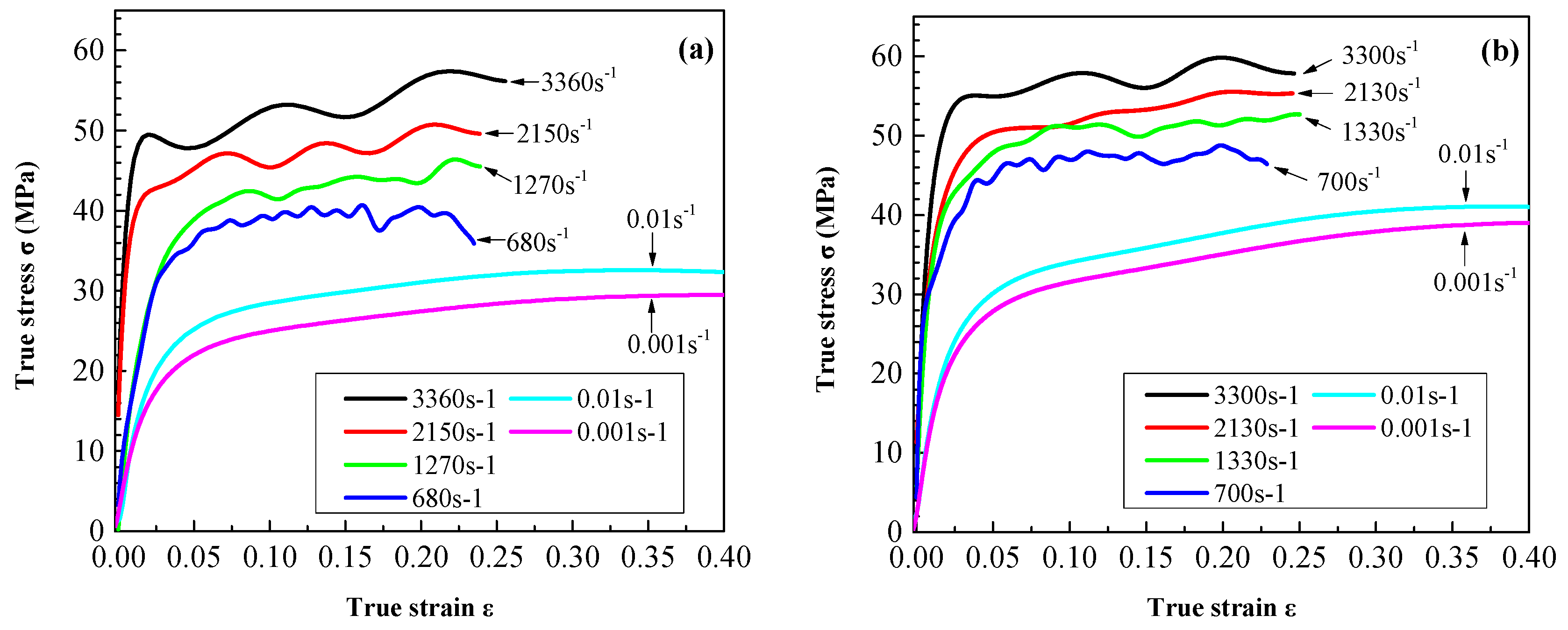

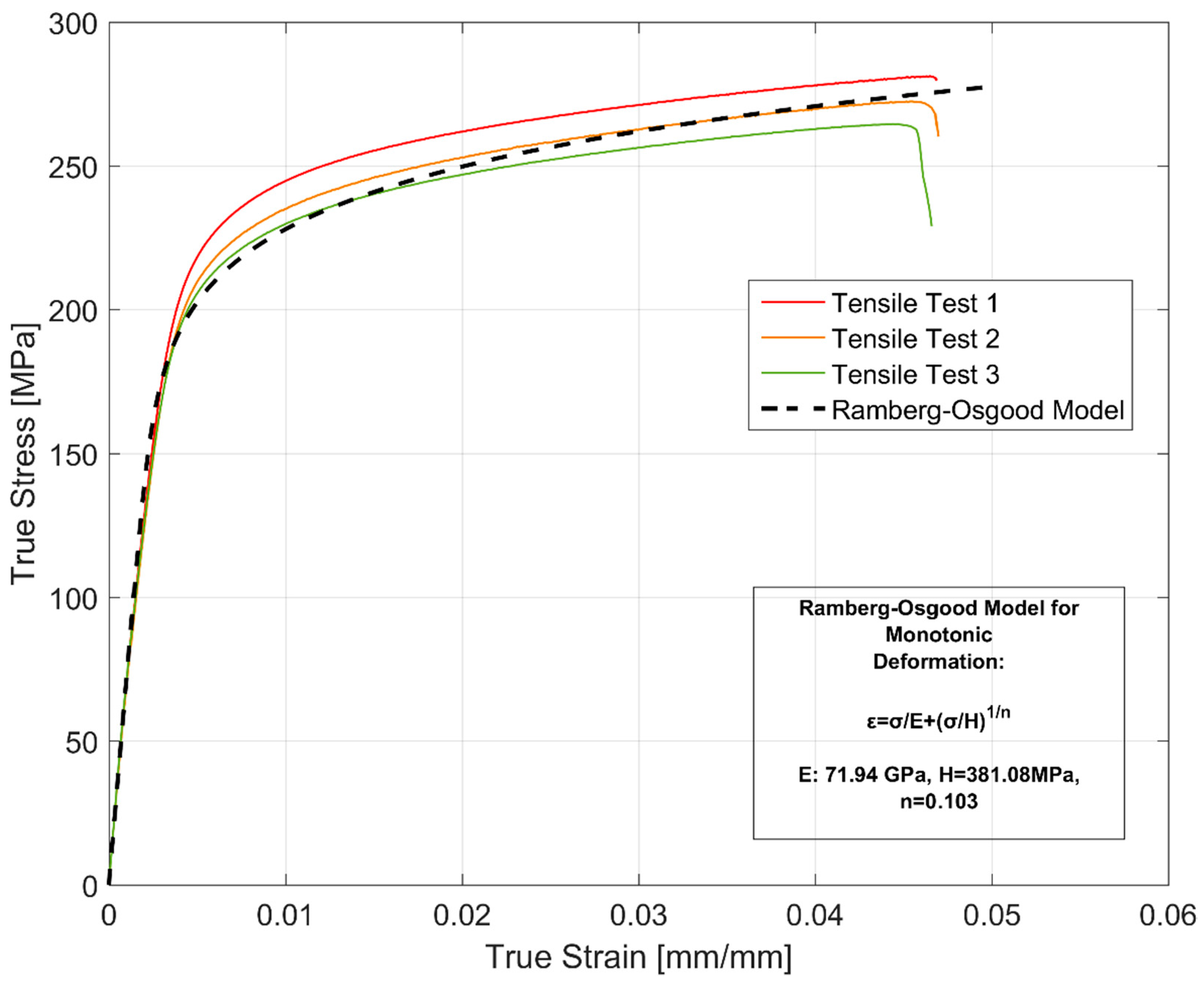

Stress strain behavior determination ceramics. The stress strain behavior for al 2 o 3 of different grain size for three different mg psz grades and for various differently composed duplex structures is investigated and compared with their flaw resistance k r curve behavior and thermal shock behavior measured in previous works. Enquiry into such aspects of the behavior of materials is essential in assessing the material properties. This reversible behavior often shows a linear relation between stress and. 1 2 tensor notation for stress 5 1 3 stress in rotated coordinate system 8 1 4 principal stress 11 1 4 1 principal stresses in three dimensions 15 1 5 stress invariants 16 1 6 stress deviator 16 1 7 strain 17 1 8 true stress and true strain 20 1 8 1 true strain 21 1 8 2 true stress 22 problems 23 2 types of mechanical behavior 27 2 1.

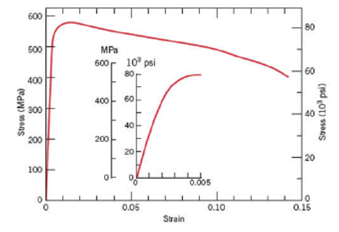

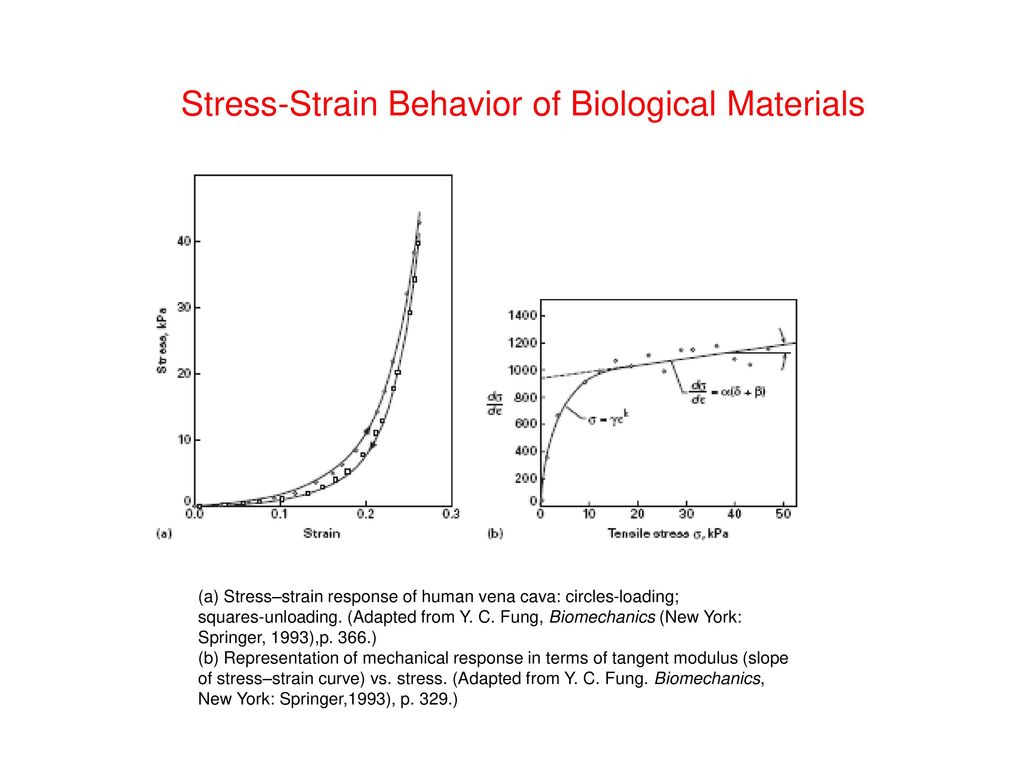

With the sample geometry a stress strain curve can then be generated from the recorded load and displacement. It s also called modulus of rupture fracture strength or the bend strength. In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength. Stress strain behavior of ceramics flexural strength.

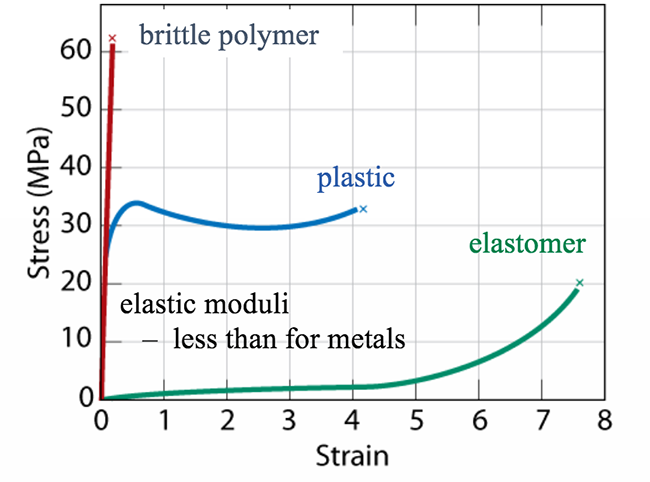

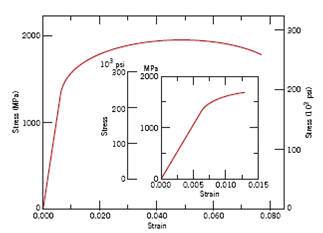

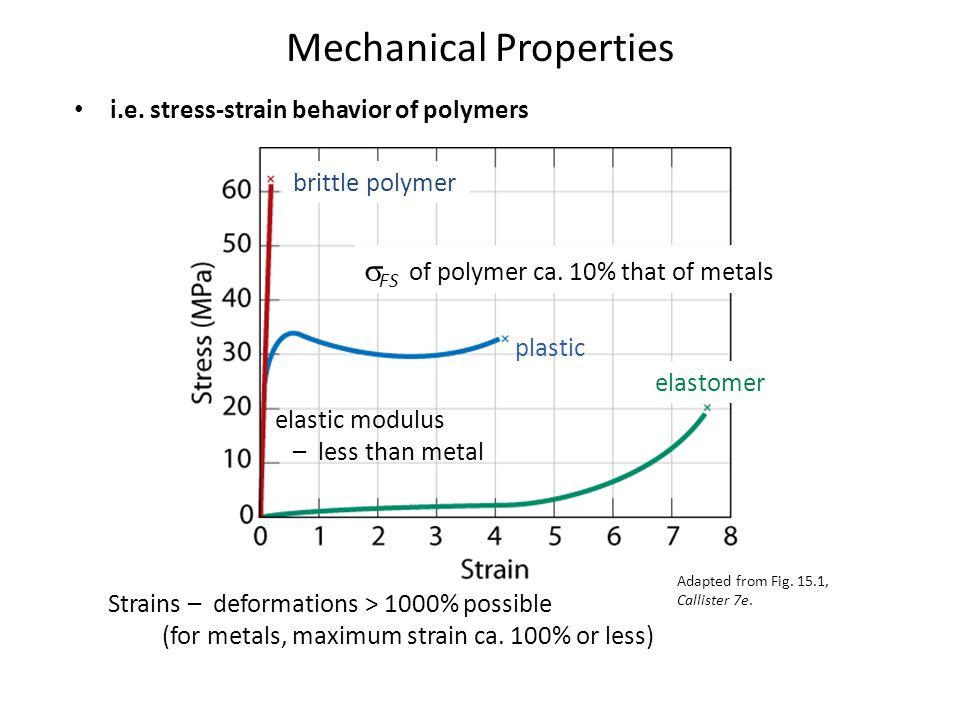

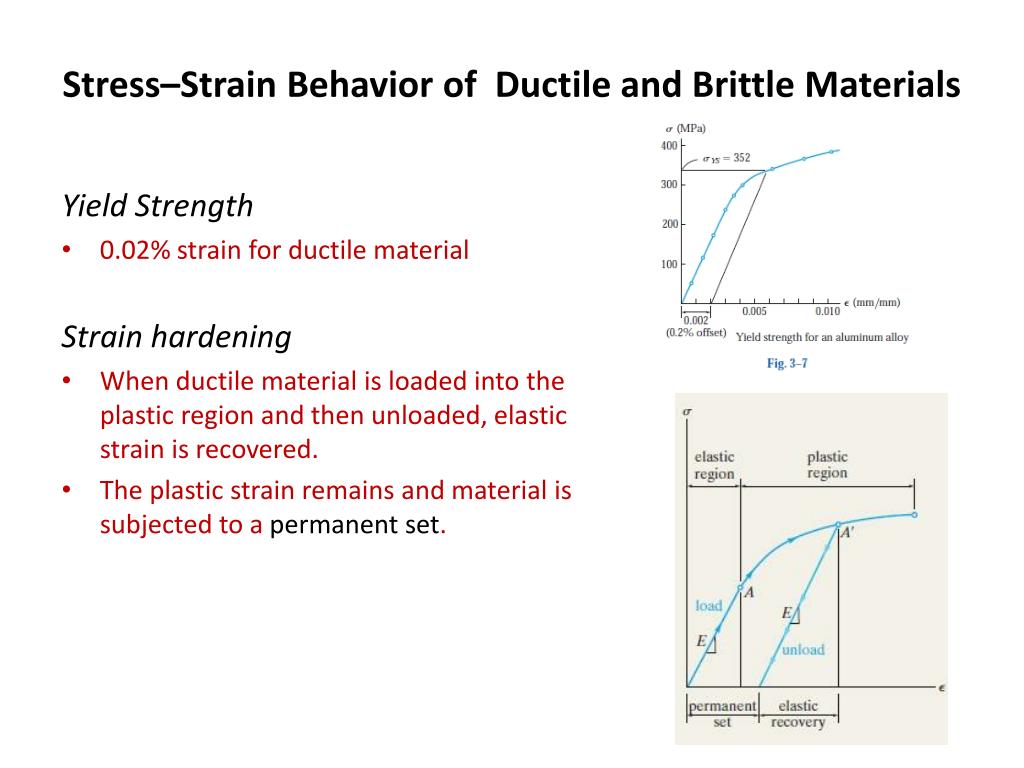

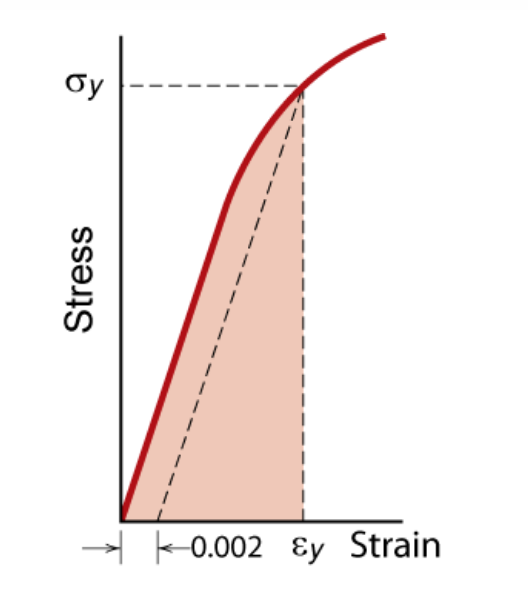

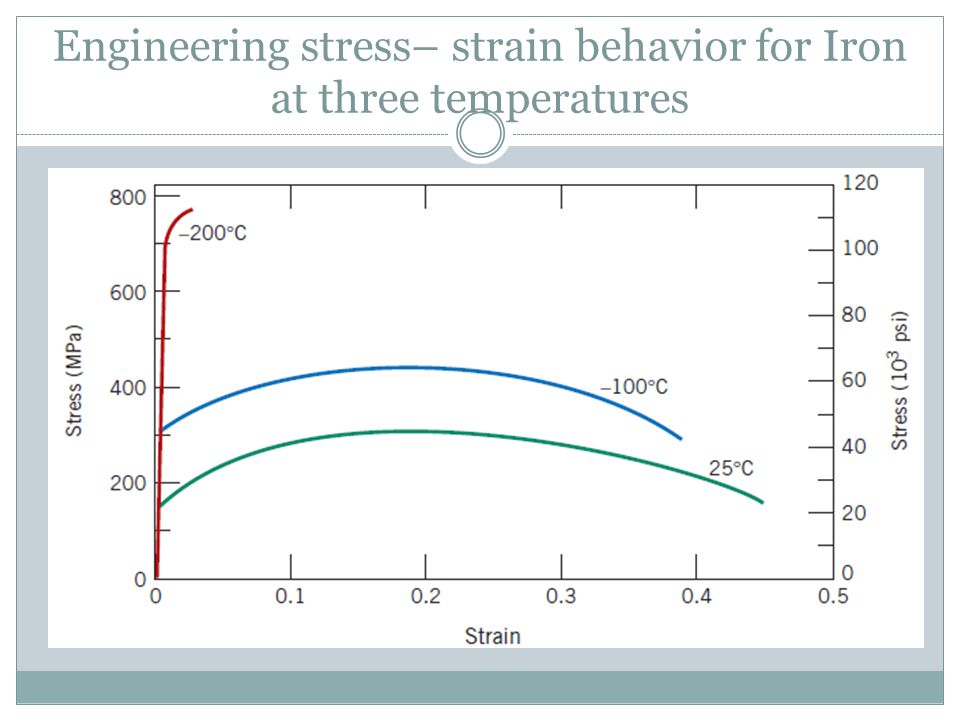

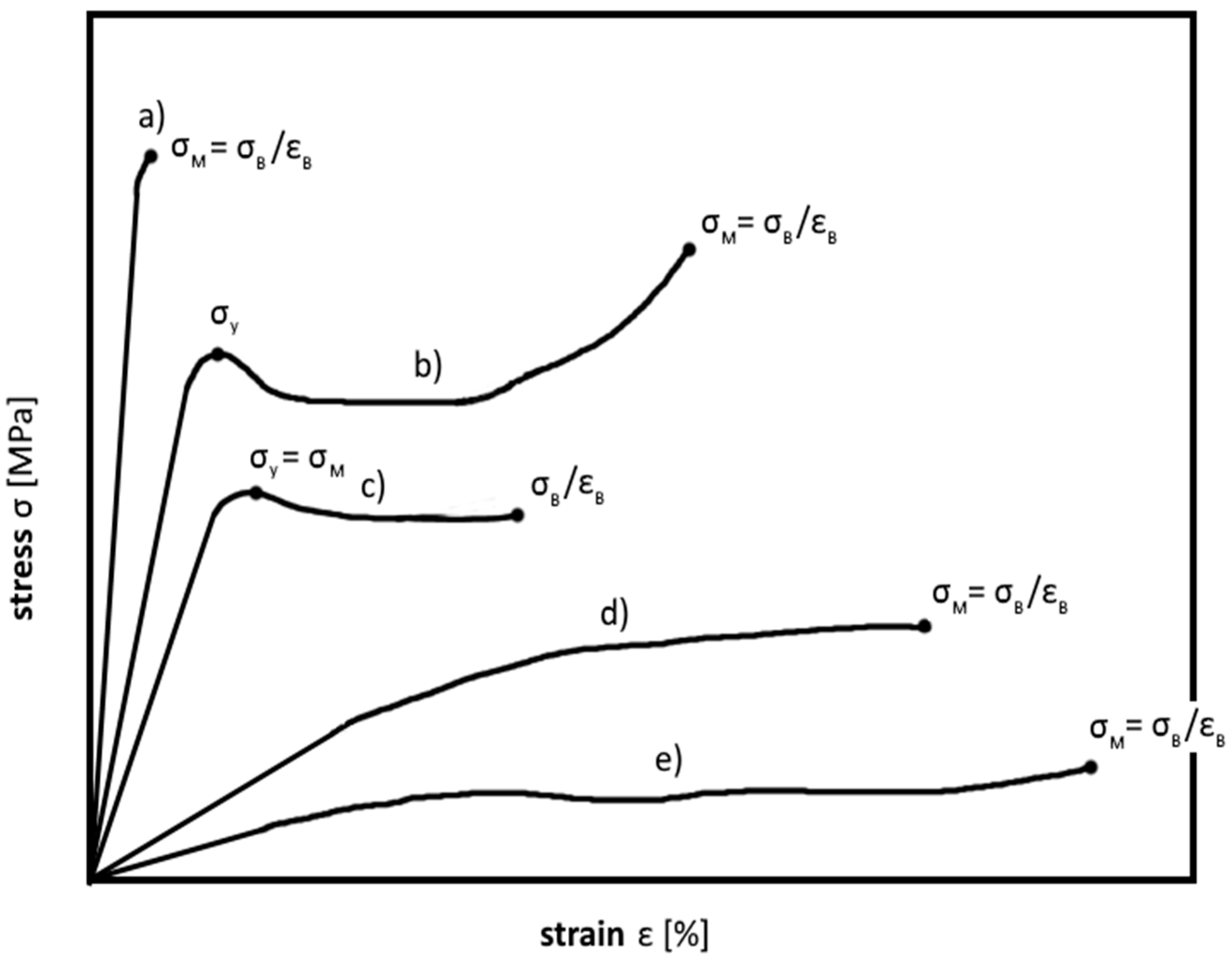

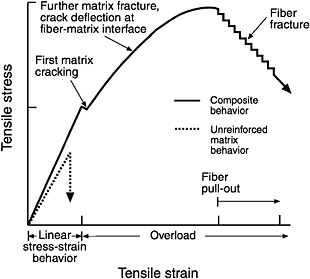

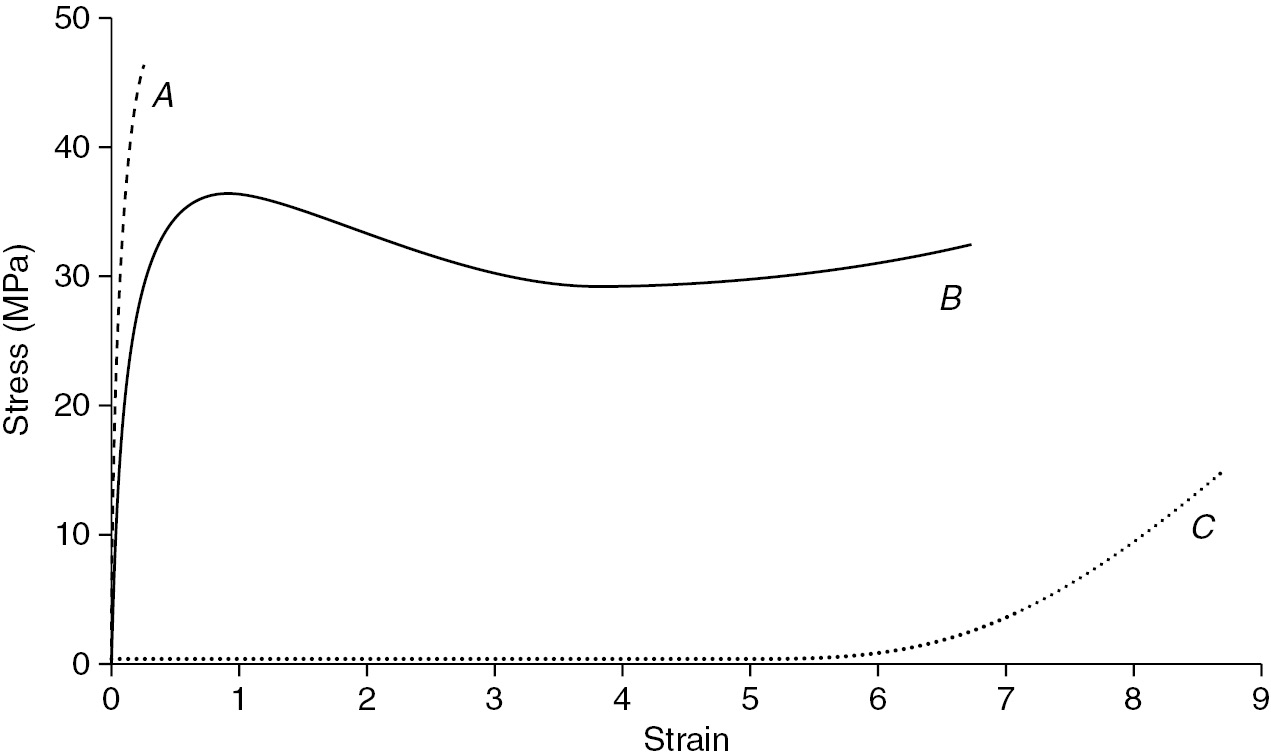

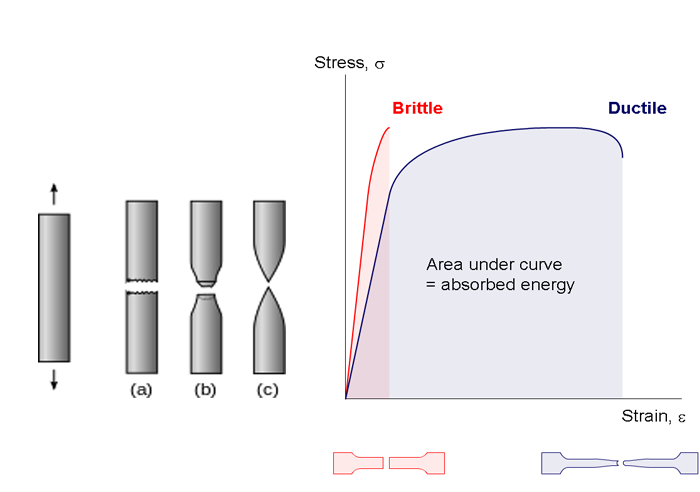

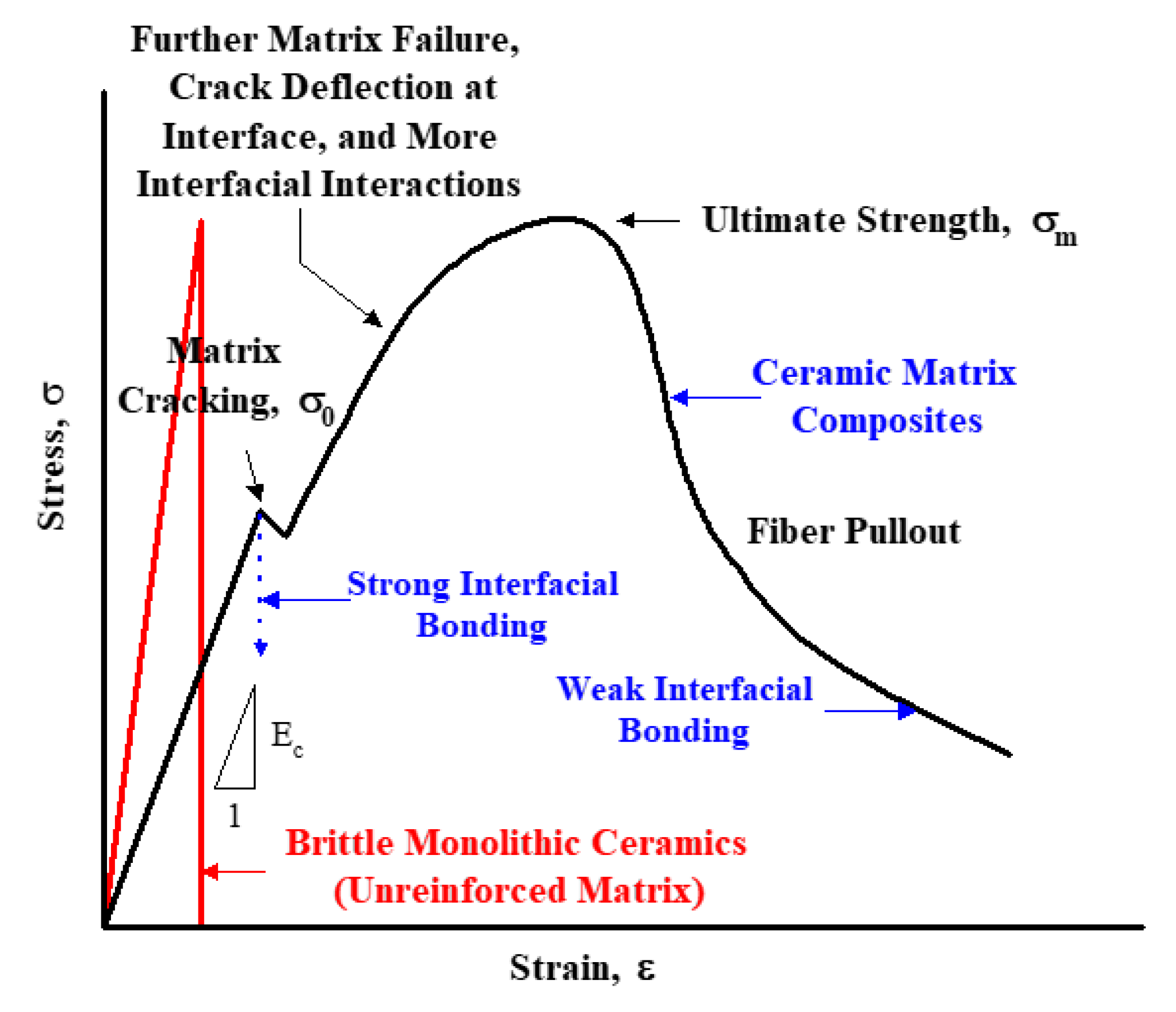

Engineering tensile strain ε engineering tensile stress σ small toughness ceramics large toughness metals adapted from fig. 1 2 typical stress strain curve of a ductile metal2 the material initially behaves in a linear elastic manner. Stress strain behavior 6 3 a specimen of aluminum having a rectangular cross section 10 mm 12 7 mm 0 4 in. These are size independent measures of load and displacement respectively.

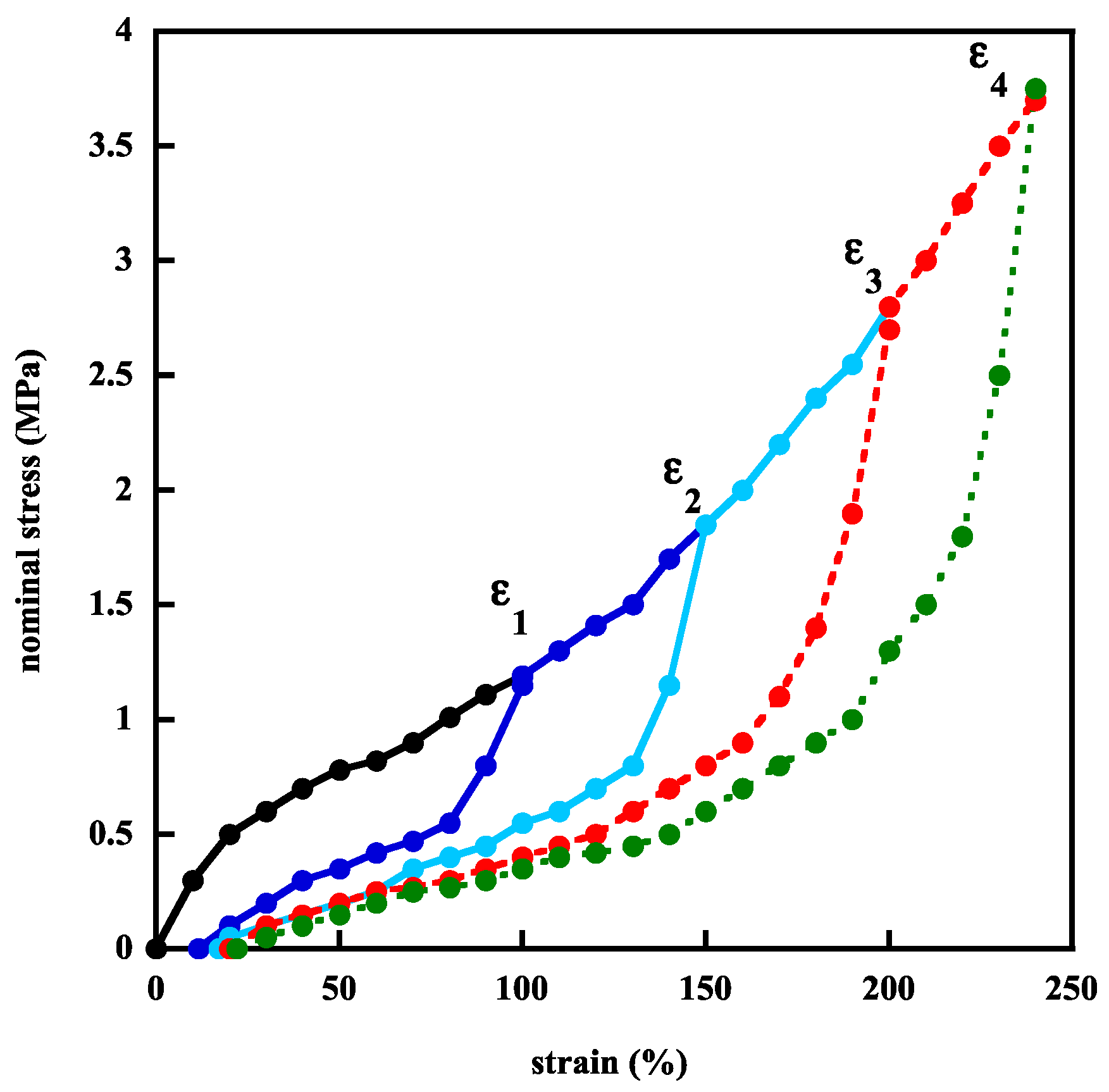

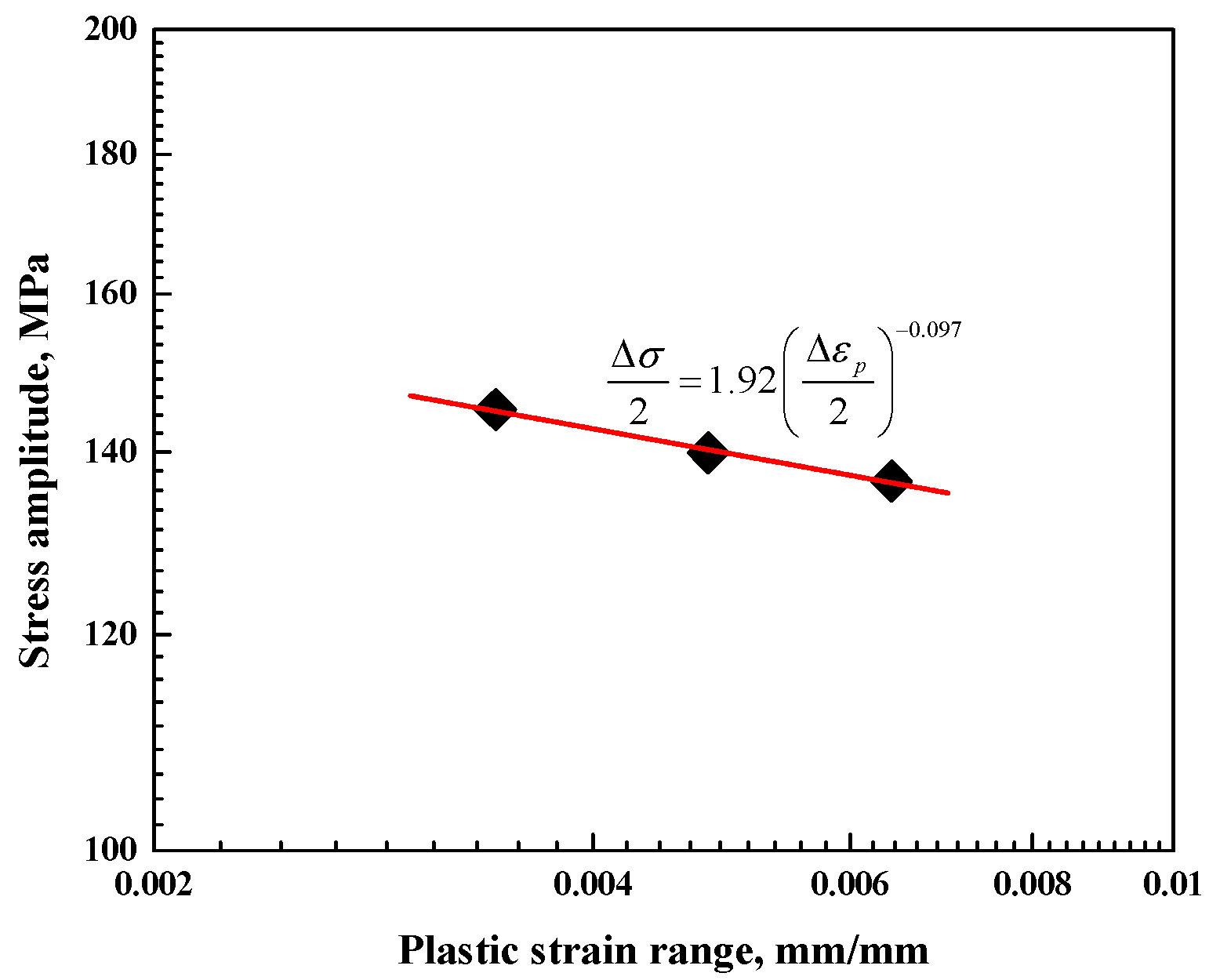

3 point bending tests 3 2 2 3 r f l bd f l f fs f fs. Stress and strain. Stress and strain are linearly related and. The experimental results seem to reveal that for most materials quasi ductility increases with.

The nonlinear stress strain behavior size dependent strength fracture mode transition and other phenomena are not adequately explained by the classical concepts of the mechanical behavior of materials and mechanics of fracture 28 30. A typical stress strain profile for a ductile metal resembles the following.