Stress Vs Strain Curve For Ceramics

Stress vs strain curve.

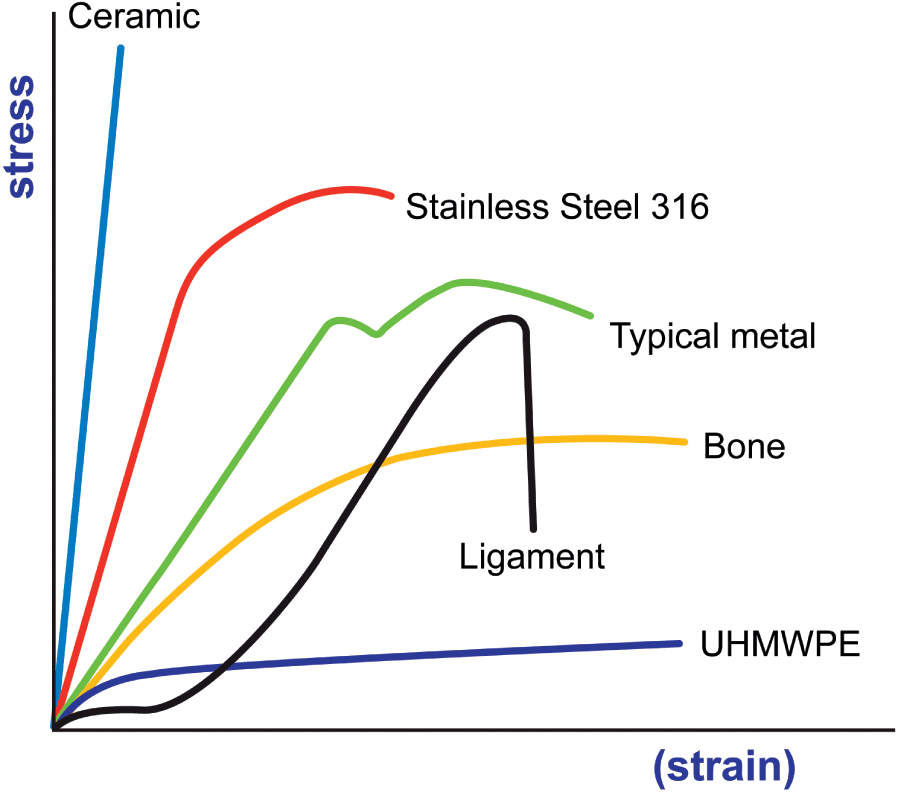

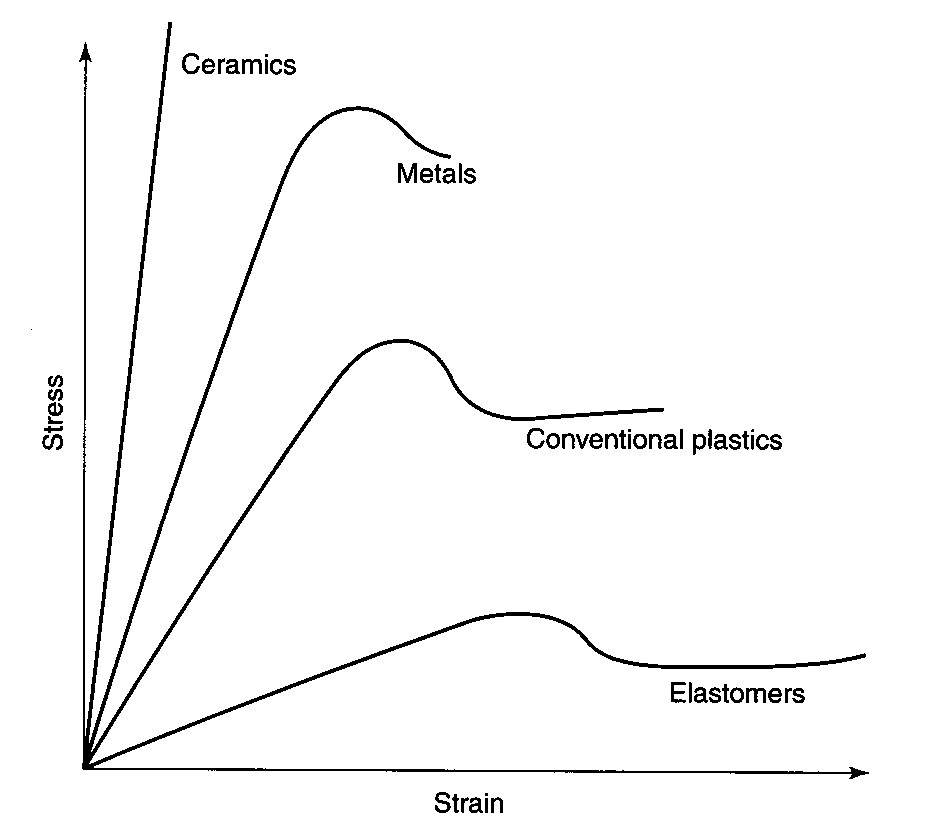

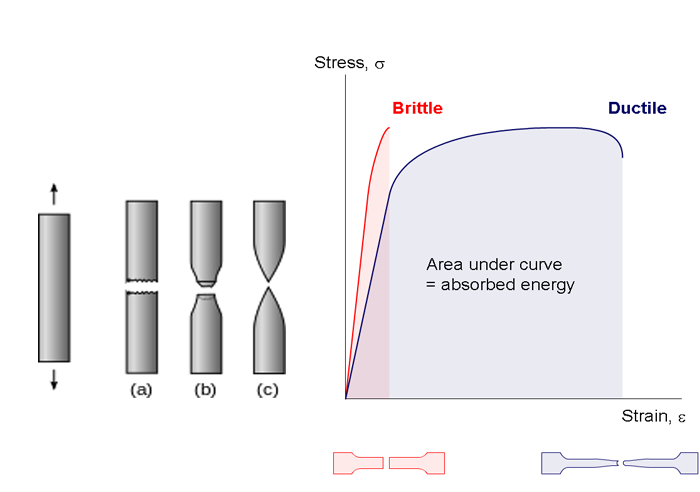

Stress vs strain curve for ceramics. While some of the stress strain curves for polymers might look similar to ones for metals polymers are mechanically different than metals or ceramics. With a very short elastic region but highly capable of supporting huge stresses. Stress is the ratio of applied force f to a cross section area defined as force per unit area. In this the stress is plotted on the y axis and its corresponding strain on the x axis.

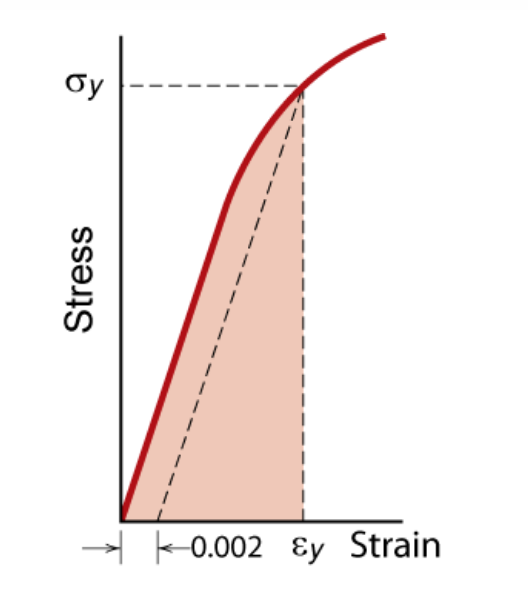

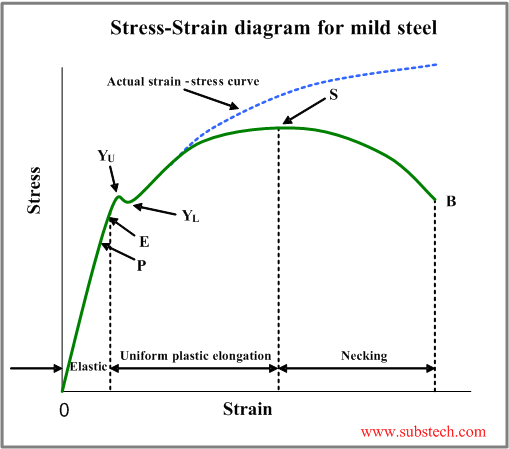

In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength. Printed in great britain 0956 7151 95 00204 9 indentation stress strain curves for quasi ductile ceramics a. Compressive stress stress that tends to compress or shorten the material acts normal to the stressed area. Elastomers are the ones that strains more w a lower stress.

For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity. With the sample geometry a stress strain curve can then be generated from the recorded load and displacement. 2 stress strain curve for ceramics. And finally analogous to ceramics are the stiff fibers and rigid plastics.

Shearing stress stress that tends to shear the material acts in. Stress strain curves for two brittle materials. The engineering stress strain curve does not. Received 31 october 1994.

S19 s27 1996 elsevier science ltd acta metallurgica inc. Stress and strain are linearly related and. A highly elastic polymer may stretch over 10 times the original length before breaking while a metal might elastically stretch 10 of the original length elastically and may stretch. Tensile stress stress that tends to stretch or lengthen the material acts normal to the stressed area.

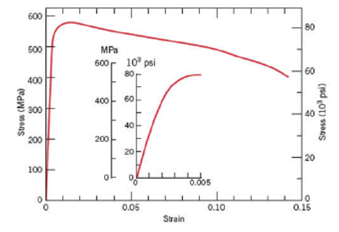

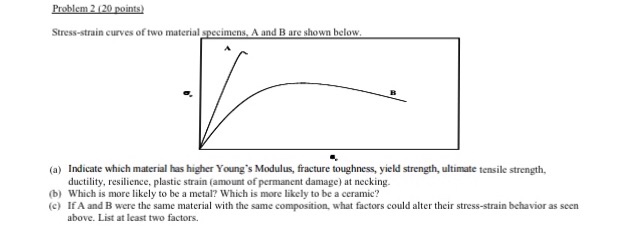

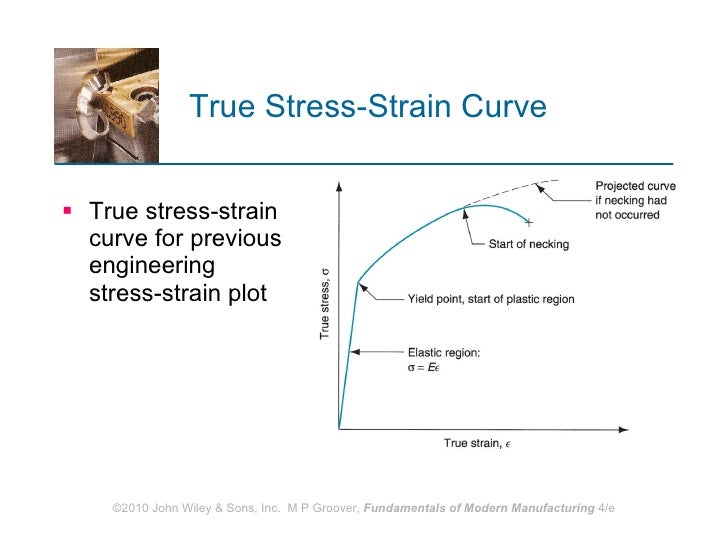

Engineering and true stress and strain the discussion above focused on engineering stress and strain which use the fixed undeformed cross sectional area in the calculations. 1 2 typical stress strain curve of a ductile metal2 the material initially behaves in a linear elastic manner. Represents straightening of the crimped ligament fibrils. The zone where a material will return to its original shape for a given amount of stress toe region applies to a ligaments stress strain curve.

1 metals al alloy stress strain curve. After plotting the stress and its corresponding strain on the graph we get a curve and this curve is called stress strain curve or stress strain diagram. Stress strain curve is the plot of stress and strain of a material or metal on the graph. True stress and strain measures account for changes in cross sectional area by using the instantaneous values for the area.