Stress Strain Curve Of Metals Ceramics And Polymers

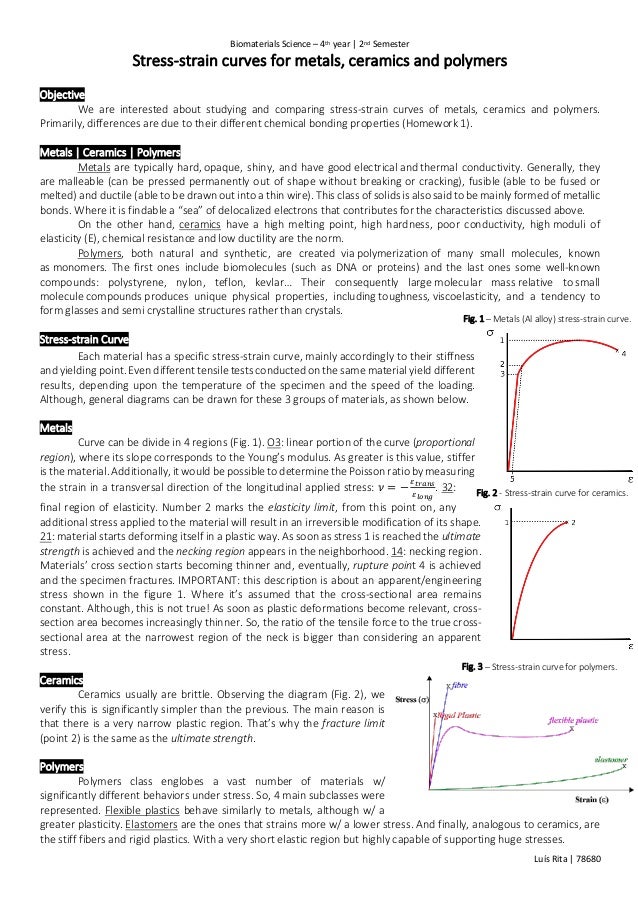

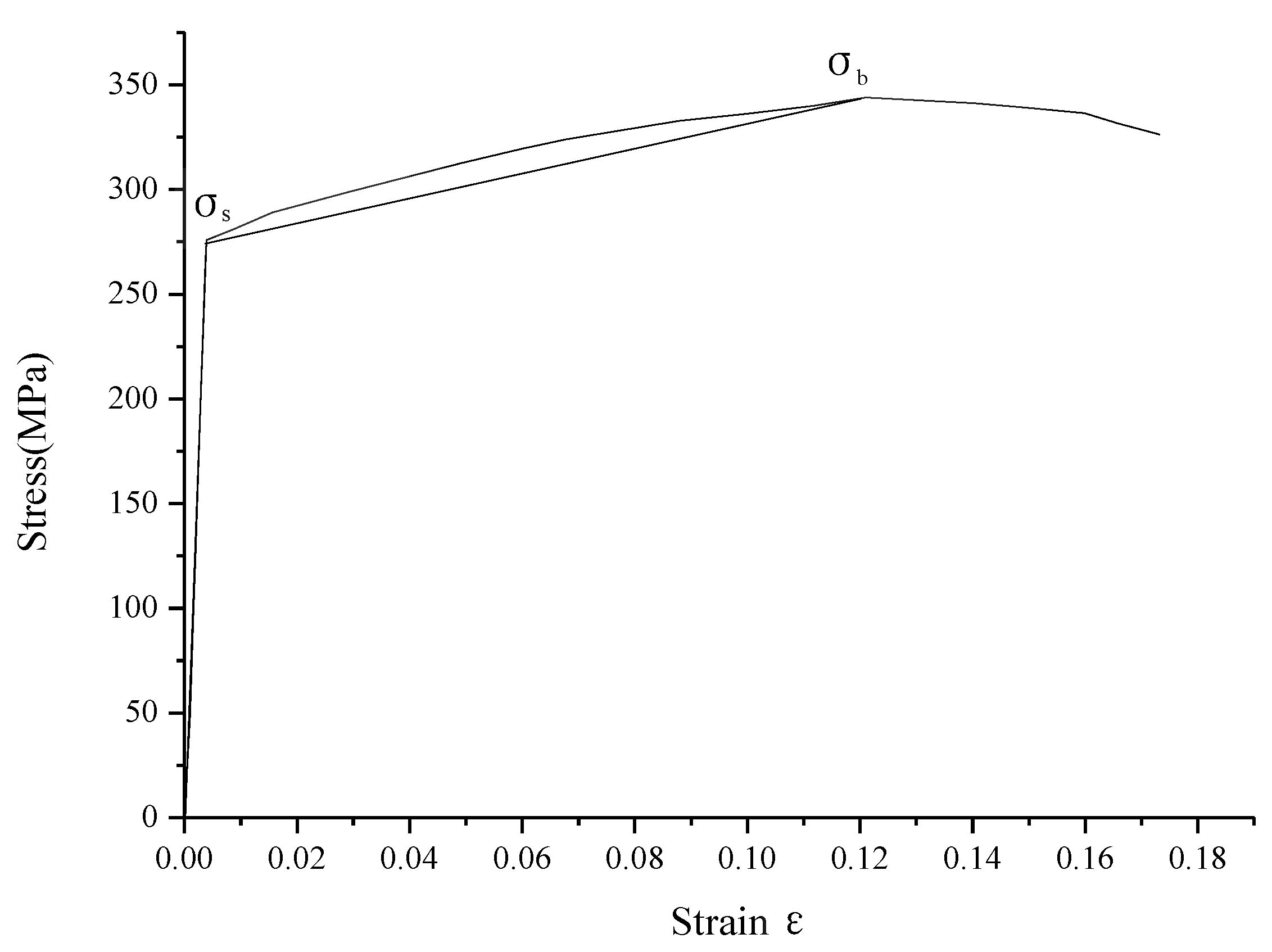

Low carbon steel generally exhibits a very linear stress strain relationship up to a well defined yield point fig 1.

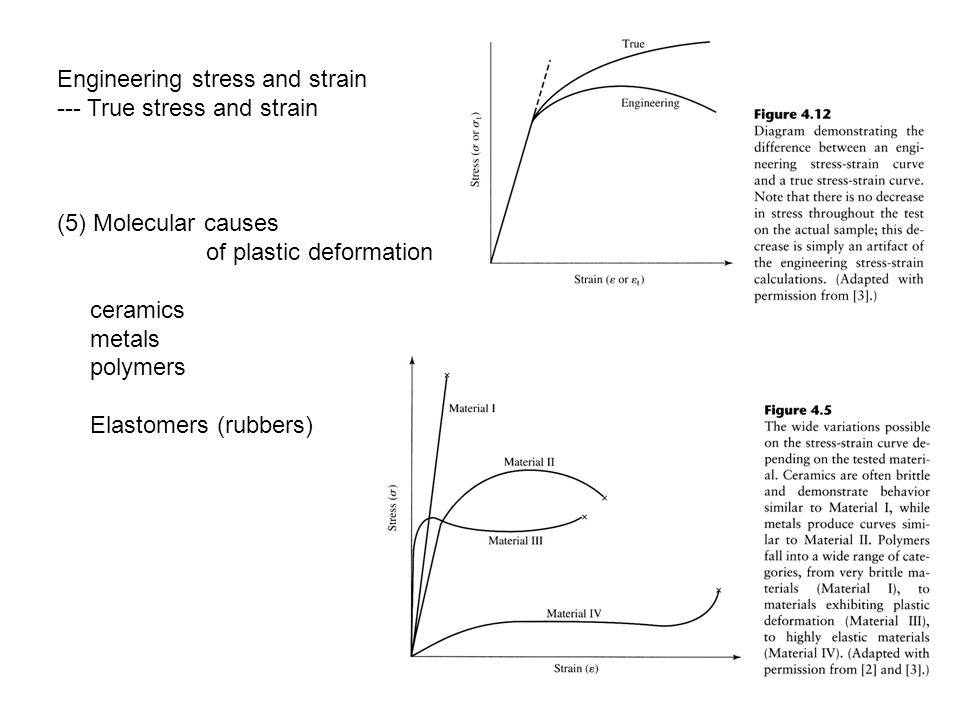

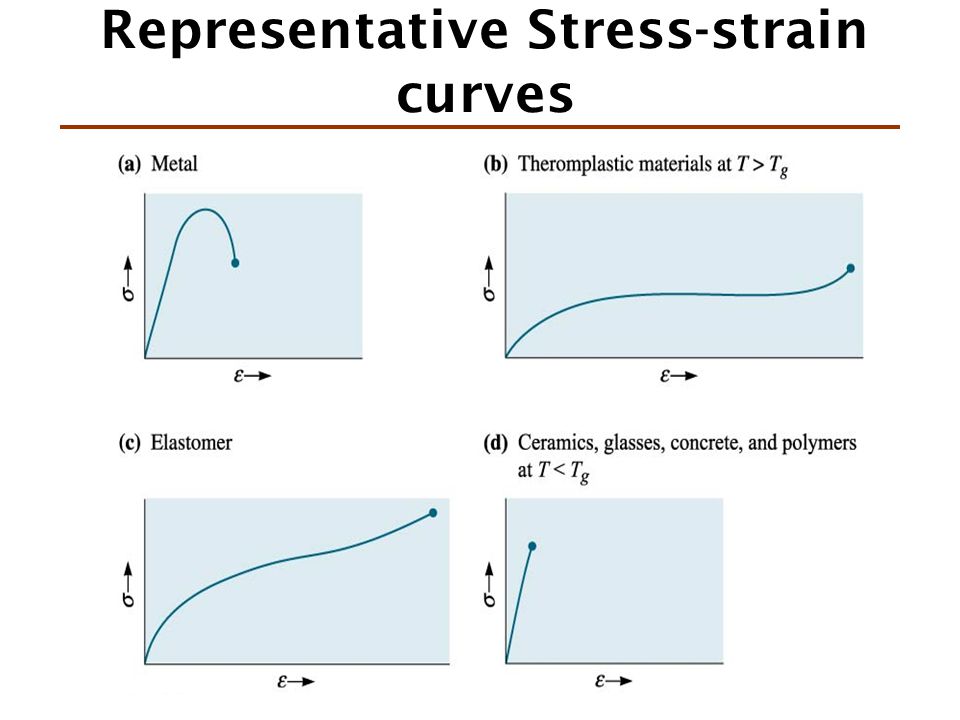

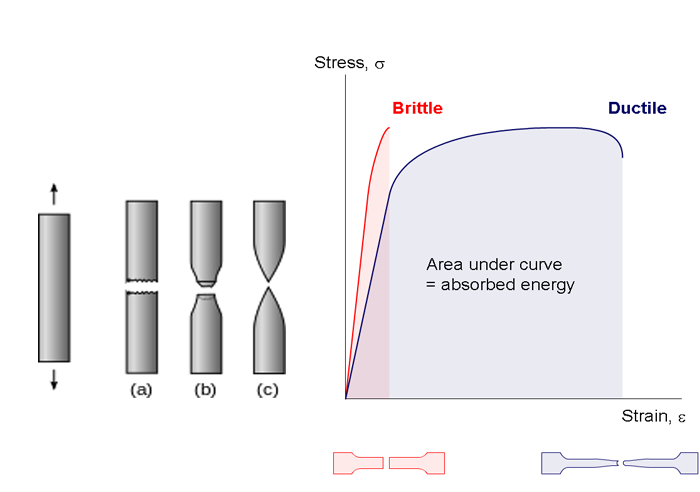

Stress strain curve of metals ceramics and polymers. Metallic bonding is great for this sort of re bonding which is why metals are usually ductile. The yield point is the maximum of the stress strain curve the weird circle symbol. This stress curve is typical for ductile metallic elements. Elasticity ductility and tensile strength those four materials can be simplified by these definitions.

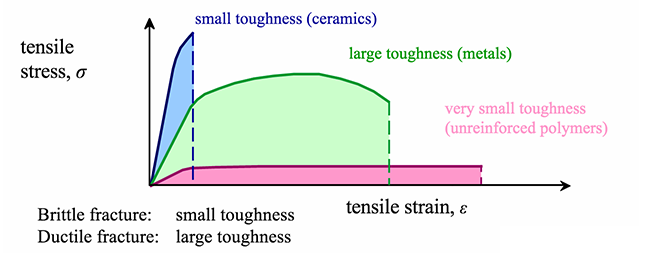

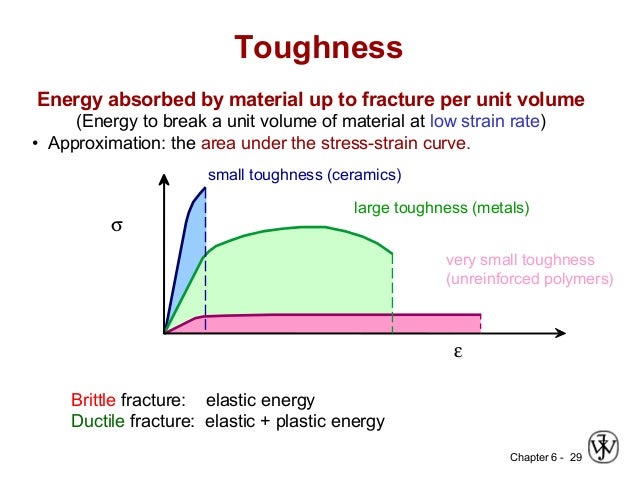

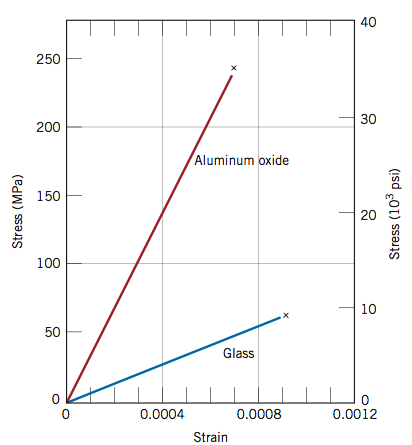

Elastic energy ductile fracture. Based on the mentioned properties. For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity. Metals and its alloys contain atoms that are arranged in orderly manner.

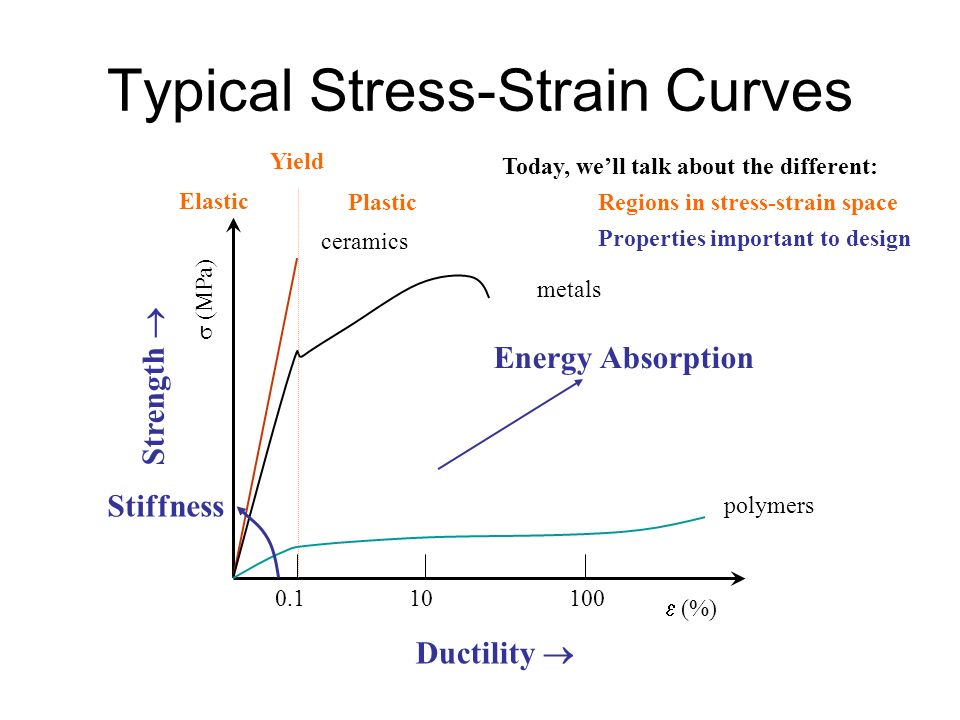

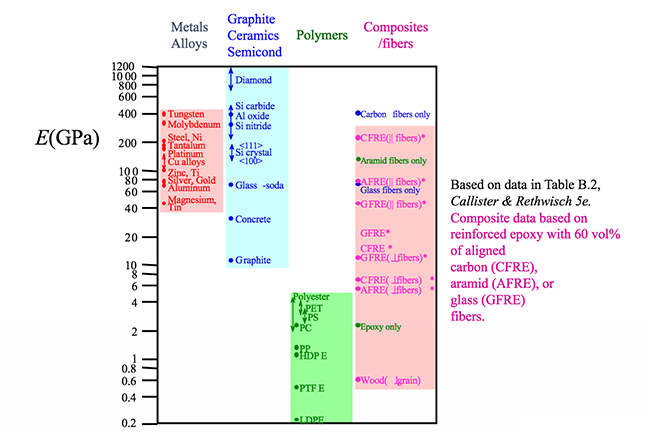

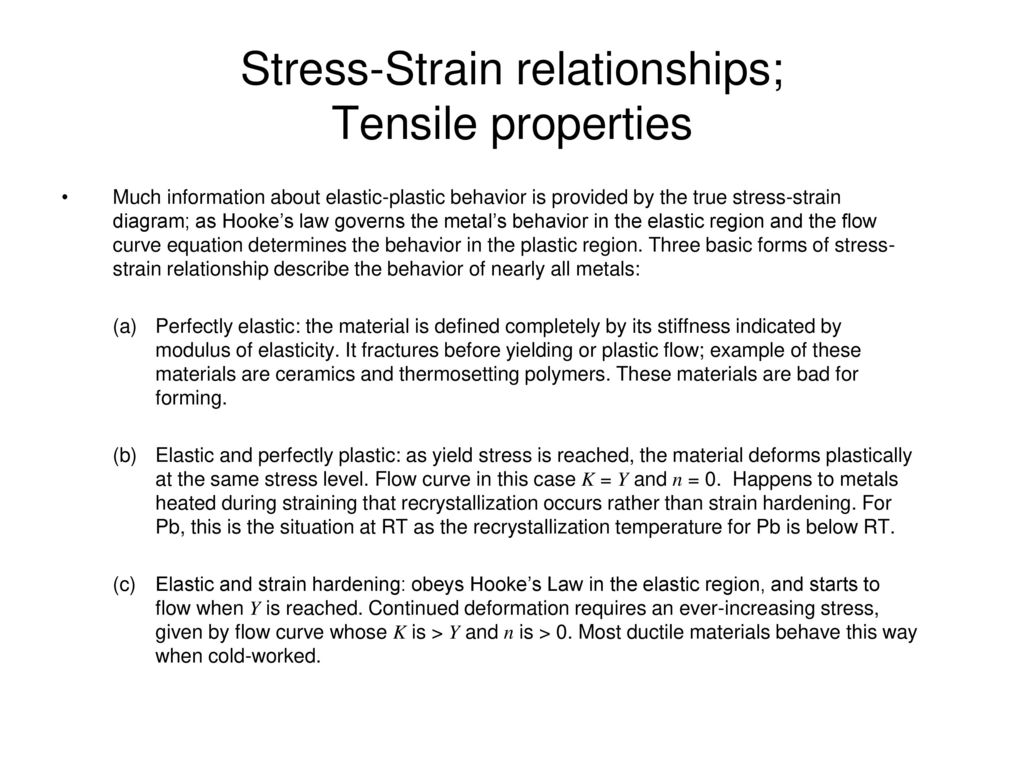

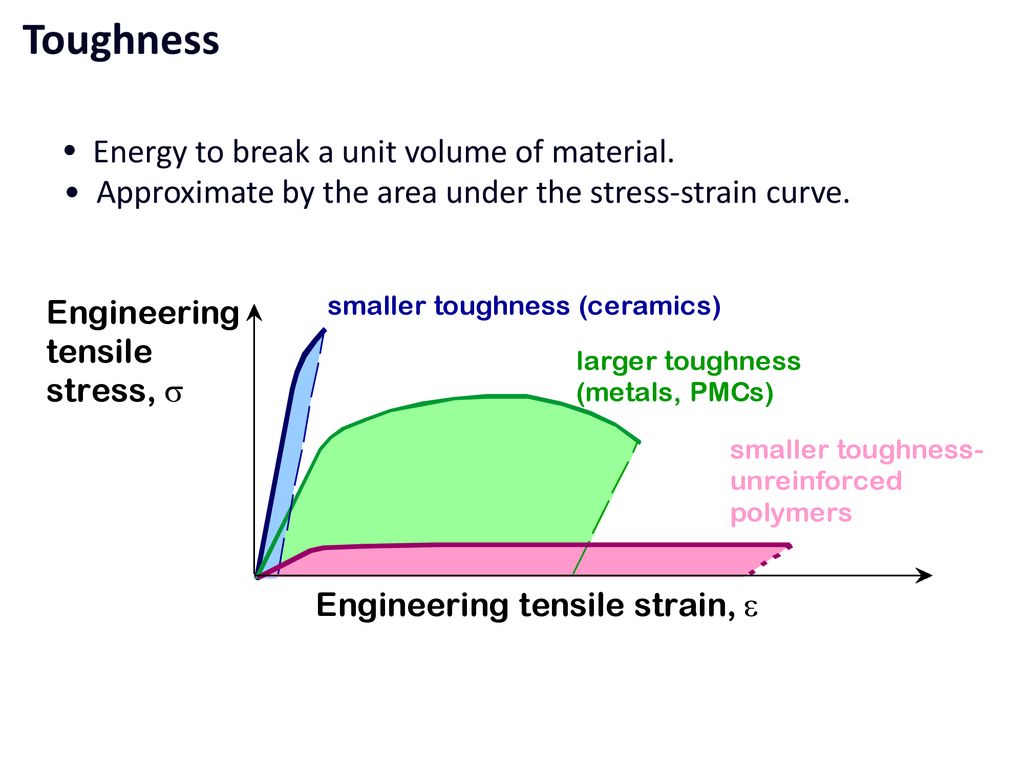

A typical stress strain curve would look like figure 6 2strain curve. Elastic plastic energy very small toughness unreinforced polymers engineering tensile strain ε engineering tensile stress σ small toughness ceramics large toughness metals adapted from fig. Difference between metals ceramics and polymers with respect to modulus and tensile strengths the modulus values for highly elastic polymeric materials are lower than those of metals. Plasticity happens when the atoms slip when they break bonds and reform new ones.

Many ductile materials including some metals polymers and ceramics exhibit a yield point. The stress strain curve for metals ceramics and polymers the curve i have shown you is a typical curve for ductile materials. In this the stress is plotted on the y axis and its corresponding strain on the x axis. Stress strain curve is the plot of stress and strain of a material or metal on the graph.

Primarily differences are due to their different chemical bonding properties homework 1. After plotting the stress and its corresponding strain on the graph we get a curve and this curve is called stress strain curve or stress strain diagram. While some of the stress strain curves for polymers might look similar to ones for metals polymers are mechanically different than metals or ceramics. Approximate by the area under the stress strain curve brittle fracture.

Stress strain curves for two brittle materials. The linear portion of the curve is the elastic region and the slope is the modulus of elasticity or young s modulus. It makes them dense and eventuall. In reality not all stress strain curves perfectly resemble the one shown in strain figure 6 2.