Strain Point Ceramics

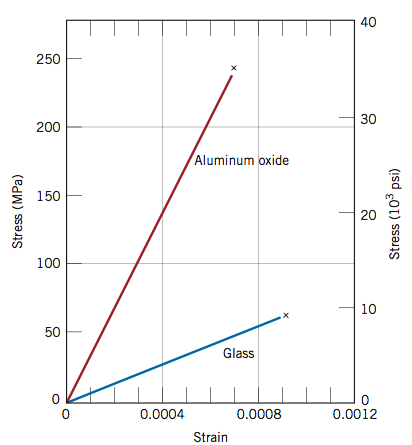

Plot the diagram and determine the modulus of elasticity.

Strain point ceramics. 1 brittle fracture characterized by no yield point a region of hookean behavior at low strains and failure characterized by chonchoidal lines such as seen in inorganic glasses. Silica refractory ceramics are often used for the containment of slags that are rich in a. Fracture strength also known as breaking strength is the stress at which a specimen fails via fracture. Electro strain is facilitated by the nanoscale structural heterogeneity.

An analysis of strains and stresses in four point bending creep tests in the limit of small beam deflections resulted in a general equation which relates the load point deflection the applied load the creep exponent n and the geometrical parameters of the loading system measurements of load point deflection rates which are experimentally easy to accomplish in ceramic systems vs. Data taken from a stress strain test for a ceramic are given in the table. The highest value of electro strain 0 74 is obtained in the lead free ceramics. 7 18 callister rethwisch.

Point defects are introduced to further enhance the strain value. The curve is linear between the origin and the first point. Past that point if more strain is added the object may permanently deform and eventually fracture. 2 yield behavior characterized by a maximum in the stress strain curve followed by yielding deformation which is usually associated with crazing or shear banding.

All of the above. Alumina for example has a tensile strength of 20 000 psi 1138 mpa while the compressive strength is 350 000 psi 2400 mpa. As for the tensile strength point it is the maximal point in engineering stress strain curve but is not a special point in true stress strain curve. Transparent refractory glass ceramics based on 10 nm crystals of spinel solid solution in a highly siliceous residual glass can be produced from compositions in the sio 2 al 2 o 3 zno mgo tio 2 zro 2 system.

What is the viscosity value corresponding to the strain point of glass. Three point bending apparatus used determine stress strain behavior. For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity. A 10 pa s b 103 pa s c 4 x 106 pa s d 1012 pa s e 3 x 1013 pa s.

Because engineering stress is proportional to the force applied along the sample the criterion for necking formation can be set as δ f 0 displaystyle delta f 0. For a metal the compressive strength is near that of the tensile strength while for a ceramic the compressive strength may be 10 times the tensile strength. Ceramics tend to be weak in tension but strong in compression.