Strain Gauge Material Should Have Low

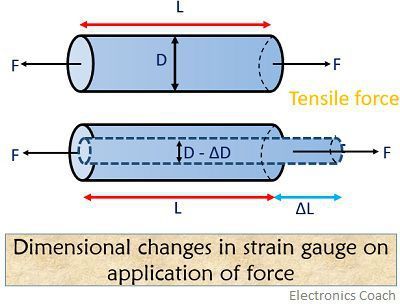

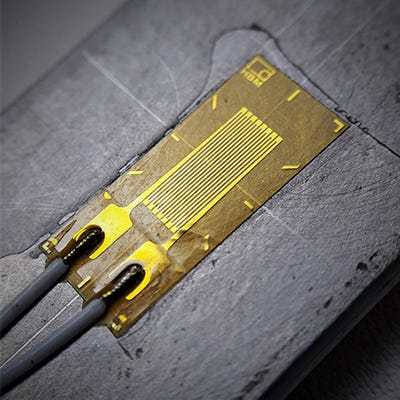

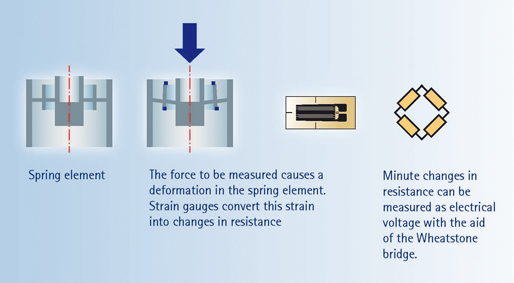

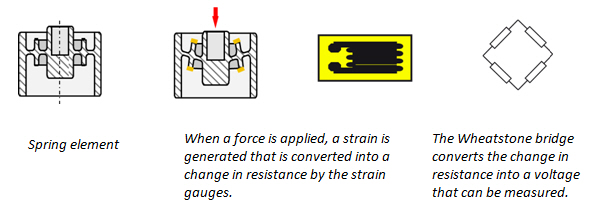

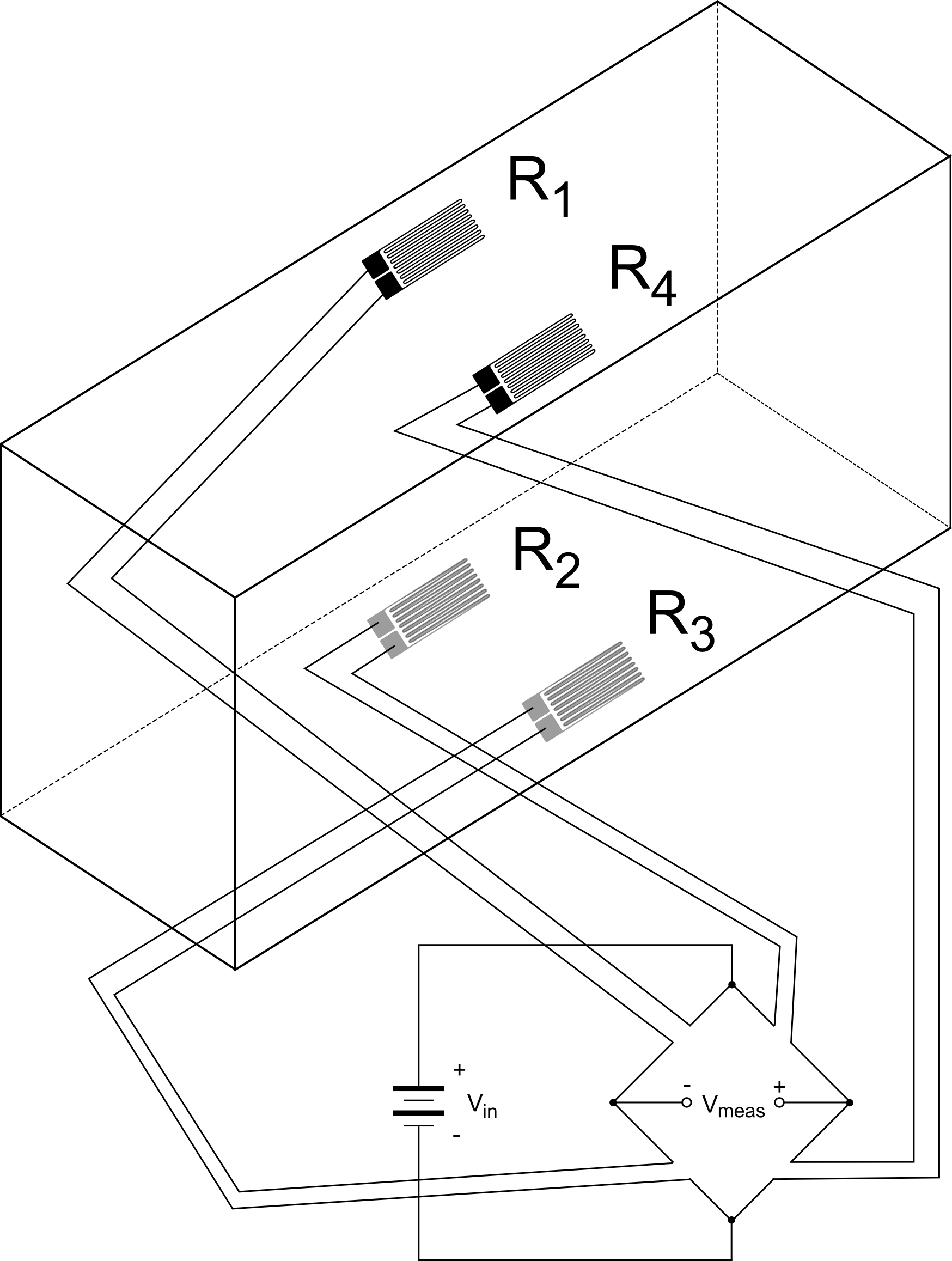

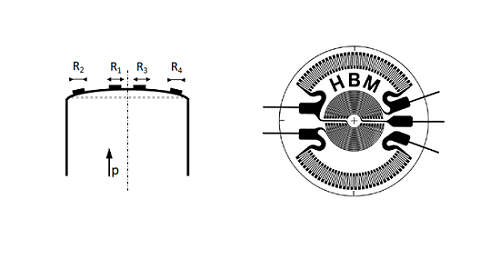

The strain gauge can also measure displacement force by the strain in a fixed arm generally described as a load cell.

Strain gauge material should have low. Applications involve low temperature environment as low as 269 c 452 f or temperatures that may vary during the measurement. The change in resistance is calibrated in terms of either load or displacement. Mechanical measurements. Strain gauge thermistor none of the above.

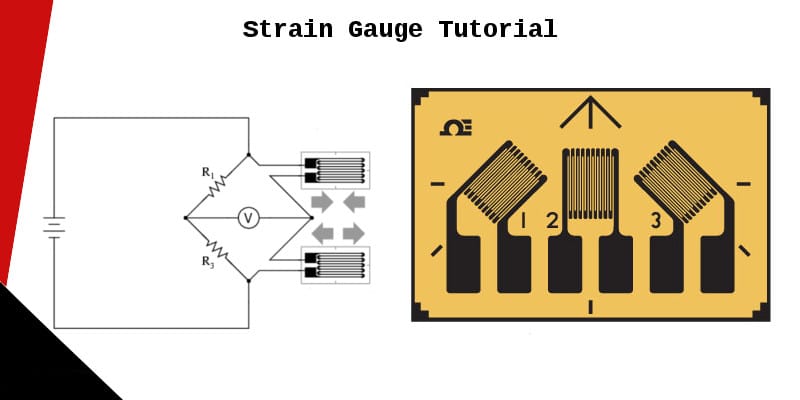

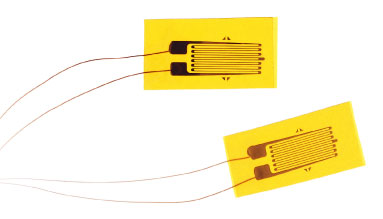

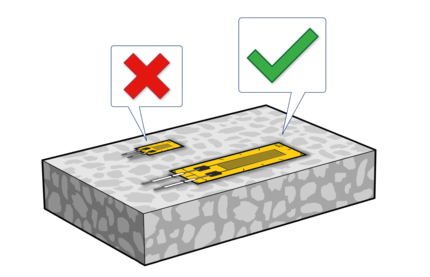

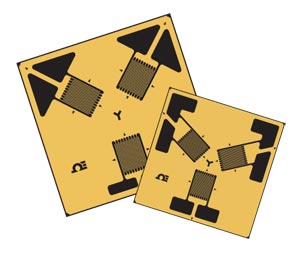

Soldering is not an issue. Unlike semiconductor strain gauges metal strain gauges change their resistance due to geometry changes. Custom strain gauges can be designed to simplify strain gauge installation for a specific application or for an environment where space is limited. Although metals also show some piezoresistive effects they are usually very small compared to those of semiconductors.

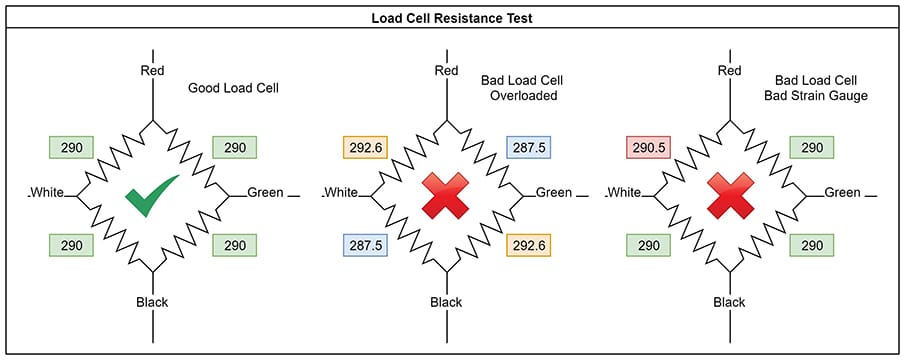

For better results a strain gauge should have low. Resistance temperature co. They are used to measure the behaviour of for example bridges and cranes under load often to detect an overload condition for safety purposes. Karma is a nickel chromium alloy and was selected as a strain gauge material for it s modulus compensating capabilities which tends to significantly reduce span shift in transducer design.

If you do not find what you need in our standard gauge selection please let us know. All of the above. This page was last edited on 21 september 2020 at 20 44 utc. Home mechanical engineering mechanical measurements.

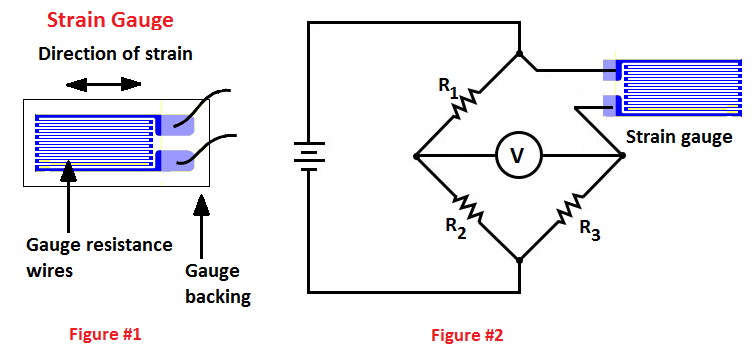

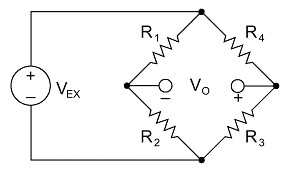

A strain gauge is a device which is when subjected to some force results change in resistance of the material. A strain gauge material should have low. The strain gauge has a specified resistance at rest which increases under strain. Resistance temperature coefficient d.

The article tells about full strain gauge theory. Text is available under the creative commons attribution sharealike license. The strain gauge was invented in 1938 by edward e simmons and arthur c ruge. The strain gauges are resistance elements that are found in a large amount of electronic equipment.

With karma alloys the gauge factor tends to decrease with increasing temperature.